Introduction

Here's what successful warehouse managers already know: while global supply chains face unprecedented disruption, the most innovative businesses are turning their biggest challenges into competitive advantages.

Yes, we're dealing with geopolitical tensions, inflation pressures, and operational disruptions that would have been unthinkable just a few years ago. But there are opportunities hidden in the chaos. Companies that invest in intelligent storage solutions now are building the resilience that will define market leaders for the next decade.

The key distinction between struggling and thriving isn't avoiding disruption; it's about being prepared for it. Success begins with considering how your warehouse can support your business when chaos ensues.

Let's explore how strategic storage solutions transform supply chain vulnerability into operational strength.

The Perfect Storm: When Everything Goes Wrong All At Once

Supply chain disruptions used to be occasional headaches. Now they're daily realities. So, what's changed? We see multiple crisis types happening simultaneously, creating compound effects that traditional logistics strategies weren't designed to handle.

Geopolitical Challenges Are The New Normal

Global Semiconductor Shortage 2020-2023

Global Semiconductor Shortage 2020-2023

Border and airspace closures, export restrictions, and sanctions can interrupt vital supply routes, causing delays in delivering goods and raising costs across industries. Today, consumers expect faster, on-time deliveries, having grown accustomed to next-day service from companies like Amazon.

The current geopolitical situation creates a complex environment for international trade. Cast your mind back to the global semiconductor shortage a few years back, which led to months-long waiting lists for cars and consumer electronics - a clear example of how political decisions in one area can ripple through global supply chains. Recent supply chain analysis shows that increasing pressures from economic instability, changing geopolitical situations, and climate risks have revealed critical stress points in global supply chains that most businesses were unaware of.

Economic Pressures Hit Where It Hurts

The reality is that inflation isn't just making your weekly shopping more expensive; it's also squeezing supply chain margins at every level. Industry analysts note that in 2025, organisations should turn to the supply chain to help reduce costs and mitigate the impacts of inflation and global instability. But that is easier said than done, especially for smaller businesses with limited power when bargaining with suppliers.

The problem is particularly acute for mid-sized operators who are caught between absorbing increasing costs (which kills profitability) and passing them on to customers (which risks their market share in competitive environments).

Daily Operations Under Constant Threat

Cargo ships rely heavily on accessible trade routes

Cargo ships rely heavily on accessible trade routes

If you thought that the big disruptions were your only worry, think again. Recent industry reports highlight how supply chain disruptions, from extreme weather events and cyber attacks to the Red Sea crisis, chronic labour shortages and strikes continue to choke the movement of raw materials, equipment and finished goods.

These aren't 'once in a decade' events anymore; they're weekly operational considerations businesses are having to make. Labour shortages hit warehouse floors directly, cyber attacks can shut down entire distribution networks instantaneously, and climate events regularly reroute transportation networks with little to no warning.

Innovative Warehousing: Your Strategic Response

The companies that are getting ahead of this chaos aren't just reacting but reengineering their approach to warehousing entirely. They're treating storage facilities as strategic assets that provide operational resilience. Not just places to store boxes.

Smart Storage Technology That Truly Makes a Difference

MOVO increases storage capacity by up to 100%

MOVO increases storage capacity by up to 100%

Intelligent Racking Systems

Pallet racking that can be configured in a variety of ways, depending on your requirements, offers the flexibility modern warehouses need. From drive-in racking for high-density storage to mobile racking systems (MOVO) for maximum space use, these options adapt to changing inventory and space constraints.

Semi-Automated Storage Solutions

Semi-automatic storage systems significantly improve the efficiency of product storage and picking. Computer-controlled, vertical or horizontal storage machines easily integrate with your existing warehouse management system (WMS) but also operate effectively as a standalone solution. This provides the efficiency benefits of automation without requiring a complete overhaul of operations.

Scalable Warehouse Management

Modern WMS systems have been developed for use with storage automation. It can be used as a standalone system or connected easily to your existing WMS, providing the operational intelligence needed to respond quickly to changing conditions in your supply chain.

Space Maximisation Solutions

A dynamic, compact storage solution that offers total flexibility and is suitable for every type of goods. The condensed nature of the system creates extra space, maximising the storage area while retaining 100% accessibility. Mezzanine floors and high-bay storage systems can dramatically increase capacity with existing footprints.

Practical Flexibility for Real-World Challenges

Configurable Storage Solutions

The traditional "one-size-fits-all" warehouse model is giving way to flexible systems that adapt to changing needs. Supply chain experts highlight how configurable storage solutions provide cost-effective responses to supply chain volatility.

Schuh, UK - Hi280 Multi-tier System with Mezzanine floor

Schuh, UK - Hi280 Multi-tier System with Mezzanine floor

Regardless of the industry you operate in, Dexion's range of unique storage solutions has been designed around you, ensuring you're doing things as efficiently as possible now, yet remain flexible enough to adapt as your business changes.

Strategic Space Use

Every year, we help scores of companies to become more efficient and more productive. We provide storage products that offer long-term solutions to clients in every type of business by increasing available space through mezzanine installations, high-bay storage systems, and vertical storage solutions that grow with your operation.

Geographic Diversification

Smart operators are spreading their bets. Risk management research shows that companies should diversify their supplier base by engaging multiple vendors across different geographic areas, and the same principle applies to warehouse strategy. Multiple locations mean multiple options when regional disruptions hit.

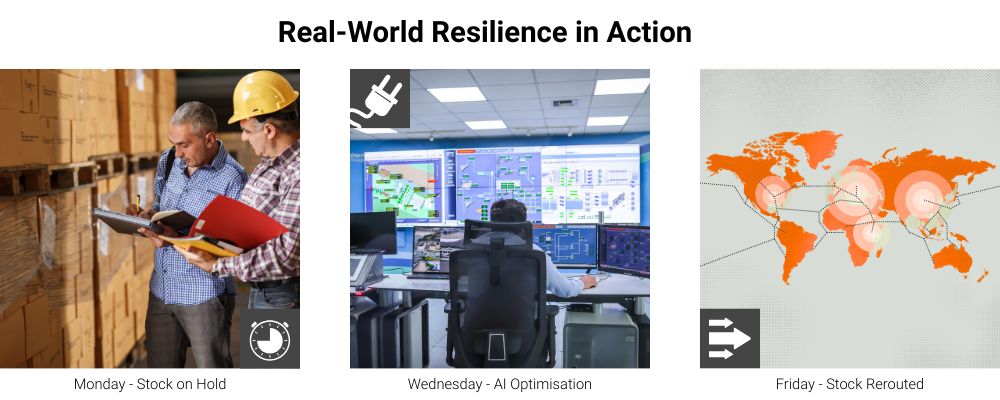

Real-World Resilience in Action

Let us paint a picture of how this works in practice:

Monday Morning: Trade tensions spike, and new tariffs threaten your biggest product line. Your warehouse holds stock that can be cleared through customs when conditions improve, not when politicians decide.

Wednesday: Energy prices jump due to geopolitical events. Your AI-optimised systems automatically shift operations to off-peak hours and adjust lighting and heating systems to minimise impact on margins.

Friday: Your primary supplier faces unexpected delays. No panic, your diversified inventory network automatically reroutes fulfilment to a secondary site with backup stock, and customers never notice the difference.

This isn't theoretical. Forward-thinking warehouses are already operating this way.

The Technology Stack That Matters

The right tech doesn't just make you faster, it makes you antifragile. Here's what's actually working:

Predictive Analytics That Look Beyond Your Walls

The best systems now monitor external factors like political events, fuel prices, weather patterns, labour disputes and give you advance warning before they impact your operations.

Real-Time Dashboards for Instant Decisions

When disruption hits, you need information fast. Modern dashboard systems let you adjust staffing, routing, and inventory levels in hours, not days. Systems like TCPlus software, which integrates with VLMs such as Tornado and GonvaLift, provide real-time visibility into inventory levels, picking performance, and system status, giving you the data needed to adapt operations instantly when conditions change.

Building Your Resilience Playbook

Here's your action plan for turning warehouse operations into a competitive advantage:

Invest in Adaptability, Not Just Efficiency

The cheapest solution isn't always the most resilient. Look for technologies and processes that give you options when things go wrong, not just speed when things go right.

Diversify Everything

Don't concentrate all your suppliers, locations, partners, and transportation routes in one place. The cost of redundancy is always less than the cost of total failure.

Build Response Teams, Not Just Operations Teams

Cross-functional teams that can respond to unexpected events with speed are now essential. Regular "what if" scenario drills aren't just good practice, they're business insurance.

Make Data Your Early Warning System

The businesses that thrive are those that anticipate problems before they occur. Invest in systems that monitor external risk factors, not just internal KPIs.

The Future is Flexible

We're not in the "predict and optimise" era anymore. The new reality requires a different approach: prepare, adapt, repeat.

The warehouses that will dominate the next decade aren't necessarily the biggest or most automated; they're the most responsive. They've built operations that bend without breaking, systems that learn from disruption, and networks that get stronger under pressure.

Whether you're a warehouse manager dealing with daily operational realities or a 3PL operator juggling multiple clients, the same principle applies: your competitive advantage now comes from how well you handle uncertainty.

The question isn't whether the next disruption is coming; it's whether your warehouse will be ready to turn that disruption into an opportunity while your competitors are still figuring out what hit them.

And that preparation starts today, whatever tomorrow brings.